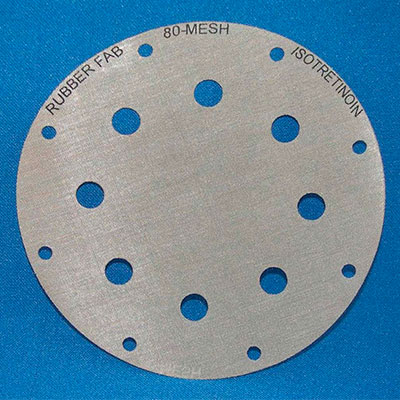

Fluidizer Tableting Bed Screens

Fluidizer Tableting Bed Screens at Affordable Prices!

Rubber Fab now offers an aftermarket Fluidizer Tableting Bed Screen Replacement Program; cost effective alternative to O.E.M replacement screen programs.

Most O.E.M manufacturers, of this type of equipment, actively promote support contracts on an a’ la carte basis, including replacement parts. These screen replacement parts are a high wear item and are extremely expensive. Some O.E.M manufacturers have specifically designed each bed unit with irregular bolt hole patterns in order to justify their replacement parts business and discourage cost effective aftermarket equivalents. In an effort to reduce costs, some tablet operations purchase bulk stainless screen and hand cut screens to fit. If the screen is not cut precisely, it can become embrittled. This cost saving practice has resulted in product recalls and product liability suits.

Sanitary Gaskets

Sanitary Gaskets Detectomer® Family of Products

Detectomer® Family of Products O-Rings

O-Rings Sanitary Hose & Hose Assemblies

Sanitary Hose & Hose Assemblies Hose Fittings & Adapters

Hose Fittings & Adapters Tubing

Tubing Sight Gauges

Sight Gauges Sanitary Clamps

Sanitary Clamps Compression Control Products

Compression Control Products Pump Replacement Parts

Pump Replacement Parts Carton Filler Replacement Parts

Carton Filler Replacement Parts Sanitary Tube Supports

Sanitary Tube Supports Food Processing Products

Food Processing Products Cheese Processing and the Dairy Industry

Cheese Processing and the Dairy Industry Sanitary Seals & Hoses for the Beverage Industry

Sanitary Seals & Hoses for the Beverage Industry Pet Food Processing Industry

Pet Food Processing Industry Alcohol Processing

Alcohol Processing Breweries, Wineries and Distilleries

Breweries, Wineries and Distilleries Cannabis Extraction Equipment

Cannabis Extraction Equipment Pharmaceutical Validation Products

Pharmaceutical Validation Products Getting the Perfect Crimp on a Hose Fitting

Getting the Perfect Crimp on a Hose Fitting Coding & Labeling Services

Coding & Labeling Services Product & Technical Services

Product & Technical Services Packaging & Drop Shipping Services

Packaging & Drop Shipping Services Quality Assurance Certification & More

Quality Assurance Certification & More Literature

Literature Part Number Library

Part Number Library Technical Articles/Documents

Technical Articles/Documents Informational Videos and Training

Informational Videos and Training Product E-Catalogs

Product E-Catalogs Case Studies – Product Innovations at Work

Case Studies – Product Innovations at Work Frequently Asked Questions

Frequently Asked Questions Rubber Fab eNewsletter Archive

Rubber Fab eNewsletter Archive