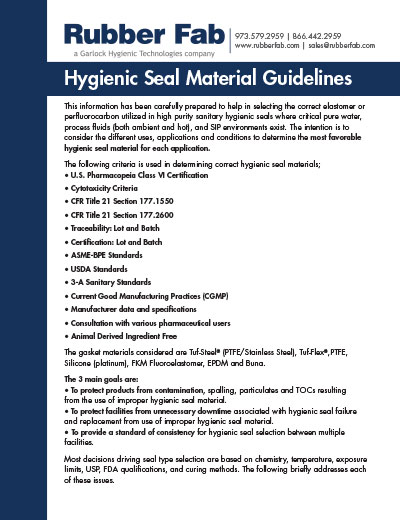

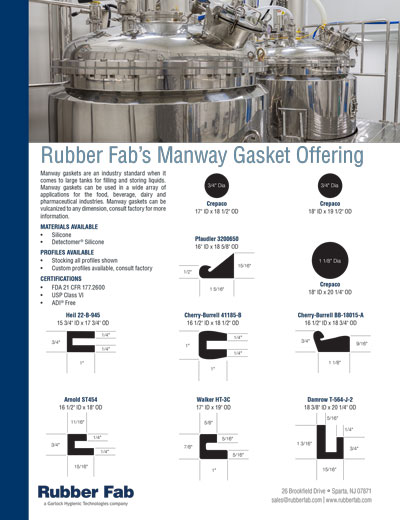

Sanitary Gasket Literature

Literature is a great resource and we have it all in one place

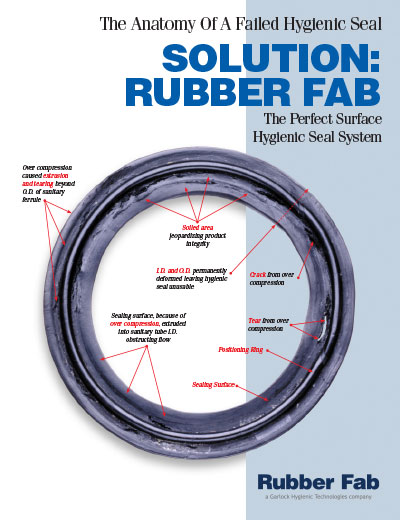

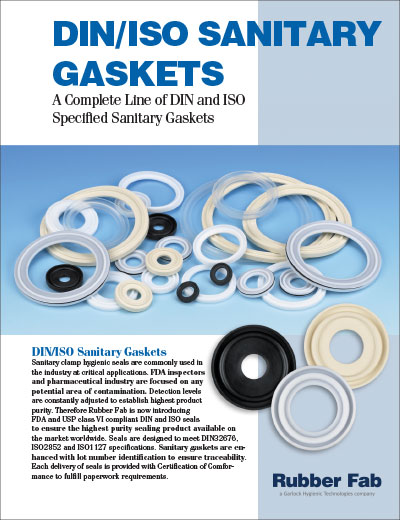

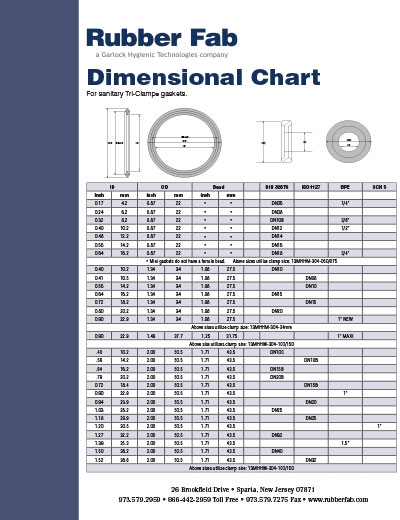

Literature is so helpful for so many reasons. It is great to have on hand when you are talking to a customer about Rubber Fab products.

Literature is so helpful for so many reasons. It is great to have on hand when you are talking to a customer about Rubber Fab products.